ABOUT

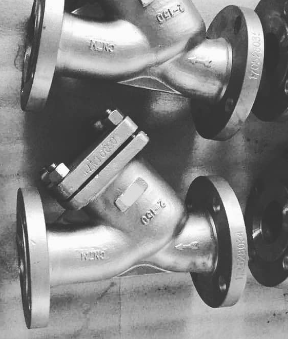

Y-Strainers are the type of machine that is used for mechanically discarding waste solids from liquid, gas or steam lines by means of a pierce or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

WORKING

Y-strainers are named for their Y-shaped design. They have a body that guards a unique designed mesh screen that filters service liquids . Other strainers use wedged wire elements or penetrate metal to filter particulates. The screening element has small openings that allow clean fluids to pass through.

Y-strainers are essential for any fluid application where fluid cleanliness is crucial . The cleanliness of service fluids affects the reliability and durability of mechanical systems in a piping system. Y-strainers can protect sensitive elements like diaphragm and solenoid valves.

Debris blocks ports of a solenoid valve and prevents diaphragm valves from full seating, causing minute leakages around them.

ADVANTAGE

● They are available in a variety of sizes and designs to meet the performance requirements of

different pipelines.

● Y-strainers can only perform their intended task if the screen is properly sized

● Engage a piping design expert when selecting Y-strainers for different applications.

● Various materials are used to fabricate Y-strainers to accommodate the operating conditions

of different processes.

● Y-strainers have seals to prevent media leakages.

● Achieving the desired performance characteristics of a Y-strainer does not conclude at the selection phase.

INDUSTRIES USING

● marine

● power generation

● petroleum

● chemical processing

COMPONENTS

● Body

● Strainer

● Gasket

● Bonnet

● Nut

● Bolt

● Tapered plug

Description:-

1. Body: Carbon Steel, CF8, CF8M, CF3M, Cast Iron, SS304, SS316

2. Nominal Diameter: DN25 to DN500

3. Nominal Pressure: Class150 to Class300

4. Inspection and Test: API 598

5. Size: ½” to 32”

6. Ends- Flanged, threaded, Buttweld, socket weld

Showing the single result