Thermodynamic steam traps have a unique operating principle which relies on the dynamics of water and flash steam. They are simple, robust and reliable and can operate up to very high temperatures and pressures. Due to their compact design and cost effectiveness thermodynamic steam traps are widely used in applications

where the condensate must be removed immediately from steam lines and steam equipment. They discharge the condensate near the saturation temperature.

Design & function of Thermodynamic Steam trap

Design

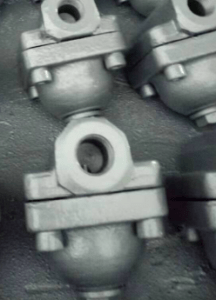

● Body style: The steam trap typically has a compact and robust design. It usually consists of a main body made from materials like cast iron, stainless steel, or brass, capable of withstanding high temperatures and pressures.

● Thermodynamic Element: Inside the trap, there is a thermodynamic element or mechanism, which is often a disc or a valve. This component responds to the temperature and pressure changes of the steam and condensate.

● Nozzle and Chamber: The trap features a nozzle through which the steam and condensate enter. The nozzle directs the flow into a chamber where the thermodynamic element is located.

● Exhaust Port: The trap includes an exhaust port or outlet where the condensate is discharged once the thermodynamic element opens.

Function:

The thermodynamic steam trap works by utilizing the difference in thermal and pressure properties between steam and condensate to control the flow of condensate. It opens when the steam pressure is higher and closes when the pressure equalizes, ensuring effective removal of condensate while retaining steam.

Advantages:

1. Durability: Thermodynamic steam traps typically have no moving parts, which means there are fewer components that can wear out or fail over time.

2. Automatic Operation: They are designed to automatically adjust to varying loads and flow rates of steam and condensate. This self-regulating feature ensures consistent performance without the need for manual adjustments.

3. Effective Operation Thermodynamic steam traps are highly effective at removing condensate from the steam system.

Description:-

1. Material: Ductile Cast Iron, Carbon Steel, Stainless

Steel,SS316,A105,f316

2. Class :150-300.PN16 PN40.

3. Size:1/2” – 1”

4. Connection type: Flanged, Threaded Butt welded, Socket Weld

Showing the single result