Strainer

As a Strainer Supplier in Dubai, UAE Valves provides industrial strainers that protect pumps, meters, turbines, and control valves from damage caused by debris and suspended solids. By removing unwanted particles before they reach critical equipment, our pipeline strainers ensure reliable performance, reduce downtime, and lower maintenance costs across oil, gas, water, power, and process industries.

How Strainers Work

Strainers are mechanical filtration devices installed in pipelines. Flow enters the body and passes through a perforated or mesh screen, which traps debris and allows clean fluid to pass downstream. Collected solids remain inside the basket or screen chamber until removed. Differential pressure across the screen signals when cleaning is due. Depending on the design, operators can clean strainers by removing the cover and basket or by flushing debris through a blow-down port without interrupting service.

Benefits of Strainers

- Shields rotating and sealing equipment from damage and unplanned shutdowns

- Maintains a stable pressure drop with screen areas sized to duty conditions

- Quick access covers and drain ports enable fast, safe cleaning

- Screens available in perforated and fine mesh to match particle size and service requirements

- Designed for seamless integration with isolation valves, DP gauges, and plant monitoring systems

Types of Strainers

- Simplex Basket Strainer – single housing with removable basket for planned shutdown cleaning

- Duplex Basket Strainer – dual housings with changeover valve for continuous operation while one basket is cleaned

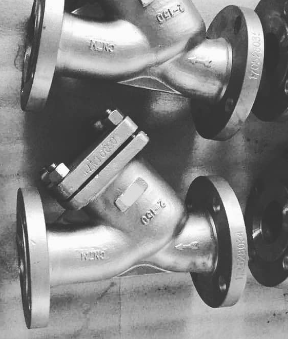

- Y Strainer – compact inline strainer for light-duty protection on steam, gas, and liquid lines

Industries Served

- Oil & Gas – wellhead utilities, produced water, fuel gas, offsites

- Water & Desalination – intake screens, RO prefiltration, distribution

- Power Generation – condensate, cooling water, boiler feed prefiltration

- Petrochemical & Chemical – process utilities and solvent lines

- District Cooling – chiller protection and debris control in networks

- Marine & Offshore – seawater cooling, ballast, and firewater systems

Technical Specifications

- Size Range: DN 15 to DN 1200 (½ in to 48 in)

- Pressure Ratings: PN 10 to PN 250; ASME Class 150 to 2500

- Temperature Range: Cryogenic service to −196 °C and high temperature up to +400 °C depending on selected materials

- End Connections: flanged RF or RTJ, butt weld, socket weld, threaded (smaller sizes)

- Screens: perforations from 0.5 mm to 10 mm; mesh from 20 to 500; customized to debris profile and required pressure drop

- Cover Styles: bolted, quick-release clamp, or davit-assisted for larger sizes

- Accessories: DP gauges or switches, drain valves, vent cocks, bypass lines where required

Design Standards

- ASME B16.34 – design and pressure-temperature ratings

- ASME B16.5 / EN 1092-1 – flange standards

- ASME B16.25 – butt weld ends

- ASME B16.10 or manufacturer standards – face-to-face dimensions

- API 598 and ISO 5208 – pressure and leakage testing

- MSS SP 61 – hydrostatic testing of steel strainers

Inspection and Testing

- Hydrostatic shell and seat tests per API 598 / ISO 5208

- Dimensional and visual inspection of body, cover, and basket

- Screen integrity, material verification, and mesh calibration

- Coating and holiday testing for water and marine service

- EN 10204 3.1 / 3.2 certification and full documentation packages

- Third-party inspection available on request

Body and Screen Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC | ASTM A216 | Hydrocarbons, steam, general service |

| Low Temperature CS | LCB, LCC | ASTM A352 | Chilled water, cryogenic and low-temperature lines |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, brackish and RO water |

| Forged Stainless Steel | F304, F316, F316L | ASTM A182 | High-pressure housings and trims |

| Duplex & Super Duplex | F51 (2205), F55 (2507) | ASTM A182 / A890 | Seawater, chloride-rich duties |

| Bronze & Aluminium Bronze | C83600, C95800 | ASTM B148 | Marine, seawater cooling, firewater |

| Nickel Alloys | Monel 400, Inconel 625 | ASTM B564 | Sour service, aggressive media |

| Screens & Liners | 304, 316, Monel mesh; 410 support | ASTM A240 / B164 | Particle separation with perforated & mesh liners |

Special Features

- Quick-change basket cartridges to reduce maintenance downtime

- Magnetic inserts to capture fine ferrous particles in hydrocarbon or water duty

- Differential pressure indicators or switches for timely screen cleaning

- Steam jackets for viscous fluids that risk solidifying at rest

- External epoxy or glass flake coatings for buried or marine exposure

- Bypass and equalizing ports to maintain flow during basket service

As a trusted Strainer Supplier in Dubai, UAE Valves supplies inline strainers engineered to international standards, delivered with full certification, and configured to your flow rates, debris profile, and maintenance practices.

Showing all 3 results