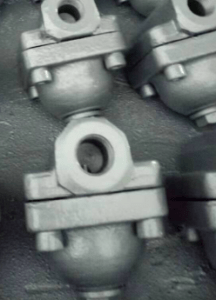

Steam Trap

As a Steam Trap Supplier in Dubai, UAE Valves provides high-quality industrial steam traps designed to improve energy efficiency and reliability in steam systems. By automatically discharging condensate and non-condensable gases while retaining live steam, our traps keep heat exchangers, tracing lines, and process loops operating at peak performance with reduced losses and stable pressure control.

How Steam Traps Work

Steam traps distinguish between condensate, steam, and air, opening or closing automatically to remove only what is needed:

- Float Type – a buoyant ball rises with condensate, lifting a lever to open the seat for continuous discharge at near condensate temperature.

- Thermostatic Type – a bimetallic or bellows element expands/contracts with temperature change, opening wide on cold start and closing as steam reaches the trap.

- Thermodynamic Disc Type – uses flash steam dynamics above the disc; it snaps shut under pressure and reopens once equilibrium is restored.

- Inverted Bucket Type – the bucket floats up with steam to shut the valve and sinks with condensate to open it, offering rugged performance and dirt tolerance.

The result is automatic, reliable drainage without wasting live steam.

Benefits of Steam Traps

- Maintains heat transfer efficiency and reduces steam losses

- Prevents water hammer, erosion, and corrosion in steam lines

- Provides rapid air venting during startup for faster warm-up

- Simple mechanisms with minimal moving parts for easy maintenance

- Options available to handle backpressure, fluctuating loads, and dirty service

Types of Steam Traps

- Ball Float Steam Trap – continuous condensate discharge, ideal for process heating and high loads

- Bimetallic Steam Trap – thermostatic element for high-temperature tracing and variable conditions

- Inverted Bucket Steam Trap – robust design with excellent dirt handling and air venting

- Thermodynamic Disc Steam Trap – compact disc type for high-pressure mains and outdoor service

- Thermostatic Balanced Pressure Trap – opens wide on cold start and seals as steam arrives

Industries Served

- Power Generation – boiler houses, PRDS stations, turbine auxiliaries

- Oil & Gas – process heaters, reboilers, steam distribution and tracing

- Petrochemical – heat exchangers, reactors, distillation columns, utilities

- Water & Desalination – auxiliary steam and condensate recovery in power islands

- District Heating & Cooling – distribution mains, tracing, interface units

- Marine & Offshore – deck heating, tracing, utility steam

Technical Specifications

- Connection Sizes: DN 15 to DN 80 (½ in to 3 in)

- Pressure Range: up to PN 40 / ASME Class 300 depending on type

- Temperature Range: service up to 425 °C for alloy steel bodies (lower for cast iron and bronze)

- End Connections: threaded NPT or BSPT, socket weld, butt weld, flanged RF or RTJ

- Installation Orientation: horizontal or vertical, depending on internal design

- Options: integral strainer, insulation covers, check valve, air vent, blowdown valve

Design Standards

- ASME B16.34 – pressure-containing parts where applicable

- ASME B1.20.1 – threaded ends

- ASME B16.11 – socket weld ends

- ASME B16.25 – butt weld ends

- ASME B16.5 / EN 1092-1 – flanged dimensions

- Manufacturer performance ratings – capacity curves, DP ranges, and live steam tightness verification

Inspection and Testing

- Hydrostatic shell and seat tests per EN 12266 / ISO 5208

- Functional bench tests for cold start, air venting, and hot condensate discharge

- Steam-tightness verification to ensure no live steam leakage at rated differential pressures

- Capacity testing against manufacturer curves where specified

- Full traceability: EN 10204 3.1 or 3.2 certification, MTCs, ITPs, and O&M manuals supplied

- Third-party inspection available on request

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Cast Iron | EN-GJL-250 | EN 1561 | Low to medium-pressure steam tracing and heating |

| Ductile Iron | EN-GJS-400/450 | EN 1563 | Higher pressure utility steam lines |

| Cast Carbon Steel | WCB, WCC | ASTM A216 | Process steam, condensate recovery, higher pressure duty |

| Stainless Steel | CF8M (316), CF3M | ASTM A351 | Corrosive condensate, clean service, outdoor duty |

| Forged Stainless Steel | F316, F316L | ASTM A182 | High-pressure traps, seats, and internals |

| Alloy Steel | WC6, WC9 | ASTM A217 | High-temperature steam systems |

| Bronze / Aluminium Bronze | C83600, C95800 | ASTM B148 | Marine and coastal service |

| Screens & Internals | 304, 316, hardened disc/seat | ASTM A240 / A276 | Long service life, erosion resistance |

Special Features

- Integral strainer screens with blowdown ports for dirt handling

- Insulation covers to reduce radiant energy loss

- Steam jackets for viscous condensate or special duties

- Air vents for fast start-up performance

- Replaceable seat/disc assemblies for extended service life

- Custom sizing for load, DP, and backpressure conditions

As a trusted Steam Trap Supplier in Dubai, UAE Valves delivers industrial steam traps engineered for efficient condensate removal, verified steam tightness, and long-term durability. Our traps are tailored to load, differential pressure, backpressure, and maintenance practices, ensuring reliable operation across Dubai’s steam networks in power, oil & gas, petrochemical, and marine sectors.

Showing all 5 results