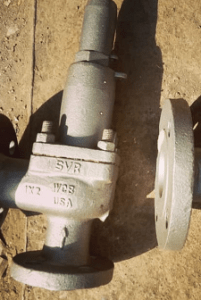

Safety Valve

As a Safety Valve Supplier in Dubai, UAE Valves provides spring loaded and pilot operated relief valves that open at the set pressure, discharge safely, and reseat cleanly so equipment stays protected. Built under ISO 9001 with PED and CE compliance, our valves are used on steam, gas, and liquid service where code compliance and uptime matter. We support engineers with sizing, documentation, and testing that match project and end user requirements.

How Safety Valves Work

A safety valve stays closed during normal operation. When system pressure reaches the set point, spring force is overcome and the disc lifts from the nozzle to release fluid. As pressure falls to the designed blowdown, the disc returns to the seat. Bellows balanced designs isolate the spring from backpressure. Pilot operated designs use a small pilot to control a larger main valve for very accurate opening and tight reseating.

Safety Valve Benefits

- Opens at the correct set pressure with repeatable performance

- Provides fast overpressure relief for vessels, exchangers, and pipelines

- Runs stably where built up or variable backpressure exists

- Reseats cleanly to limit product loss and emissions

- Delivered with clear sizing sheets and code documentation for handover

Types of Safety Valves

- Bellow Safety Valve: balanced bellows isolates backpressure and shields the spring from corrosive media

- Conventional Safety Valve: economical spring loaded construction for stable backpressure systems

- Pressure Safety Valve (PSV): pop action relief for vessels and piping on steam and gas duties

- Pilot Operated Safety Valve: pilot controls the main valve for high set accuracy and tight shutoff

- Steam Safety Valve: trim and seat geometry optimized for saturated and superheated steam

- Thermal Safety Valve: protects against thermal expansion in blocked in liquid lines

Technical Specifications

- Size range: DN 15 to DN 400

- Pressure range: about 0.5 bar to 400 bar depending on service

- Temperature range: −196 °C to +550 °C with suitable materials

- Orifice series: API lettered orifices per API 526

- Typical blowdown: 7 to 10 percent for steam and gas; 20 to 30 percent for liquid duties, adjustable in ring type designs

- End connections: flanged RF or RTJ, butt weld, socket weld, threaded for small sizes

- Options: open or closed bonnet, lifting lever, soft or metal seats, balanced bellows

Design Standards

- API 520 for sizing, selection, installation

- API 521 for pressure relieving systems

- API 526 for flanged steel PRVs and orifice series

- ISO 4126 and EN 4126 for safety devices against excessive pressure

- ASME Section VIII Division 1 for pressure vessel relief requirements

Inspection and Testing

- Set pressure calibration on certified benches

- API 527 seat tightness verification

- Hydrostatic and pneumatic tests to code requirements

- Helium leak testing for bellows balanced designs when specified

- Material traceability to EN 10204 3.1 or 3.2

As a manufacturer, we record test curves and issue serialized data packs for quality audits.

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC, LCB, LCC | ASTM A216 / ASTM A352 | Steam, hydrocarbons, general service |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, oxygen clean service |

| Forged Stainless | F304, F304L, F316, F316L | ASTM A182 | High pressure PRVs and pilots |

| Alloy Steels | WC6, WC9 | ASTM A217 | High temperature steam duty |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / ASTM A890 | Seawater and chloride rich environments |

| Super Austenitic Stainless | F44 (254SMO) | ASTM A182 / ASTM A351 | Desalination and high chloride service |

| Nickel Alloys | Monel 400, Inconel 625, Inconel 718 | ASTM B564 | Sour gas, aggressive media, high temperature |

| Hastelloy | C276, B3 | ASTM B574 / ASTM B564 | Oxidizing or halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid and chemical duty |

| Bronze / Aluminium Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and brackish water duties |

| Titanium / Zirconium | Ti Gr.2, Ti Gr.5; Zr R60702, Zr R60705 | ASTM B348 / ASTM B493 | Seawater, chlorides, specialty acids |

Industries Served

- Oil and Gas: production units, gas processing, refineries, pipelines

- Power Generation: boiler drums, superheaters, steam lines

- Petrochemical and Chemical: reactors, columns, storage tanks

- Water and Desalination: high pressure pumps, reverse osmosis trains, thermal units

- Marine and Offshore: utilities, gas compression, loading arms

- Industrial Gases: nitrogen, oxygen, hydrogen systems

As a Safety Valve Supplier in Dubai, we support existing facilities and new projects with sizing, documentation, and site testing.

Special Features

- Balanced bellows with tell tale port for backpressure monitoring and bellows integrity checks

- Adjustable blowdown rings with lock settings to stabilize reseat performance on steam and gas services

- Soft seat conversion kits for clean service; Stellite hardfaced metal seats for severe duty

- Pilot inlet filtration and damping orifices to reduce chatter under fluctuating conditions

- Test gag to allow safe hydrostatic testing without lifting the disc

- Optional bonnet styles, lifting levers, end connections, and materials to match project specifications

Showing all 6 results