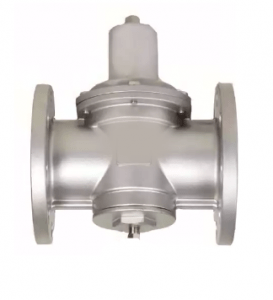

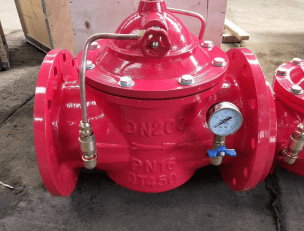

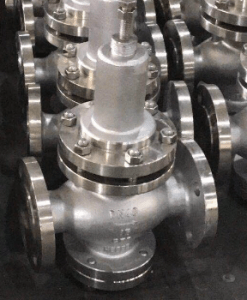

Pressure Reducing Valve

As a Pressure Reducing Valve Supplier in Dubai, we deliver engineered PRVs that maintain steady downstream pressure even when upstream conditions fluctuate. A Pressure Reducing Valve (PRV)—also referred to as a pressure regulator valve or downstream pressure control valve—helps protect pipelines, pumps, and sensitive equipment from overpressure while ensuring safe and efficient operation across utility and process systems.

How Pressure Reducing Valves Work

A PRV automatically regulates outlet pressure by modulating the seat opening:

- Direct Acting PRV – a spring and diaphragm sense outlet pressure directly, providing compact and responsive performance for point-of-use control.

- Pilot Operated Pressure Reducing Valve – a sensing pilot operates the main diaphragm, delivering higher accuracy, capacity, and stability across wide flow variations.

Both designs keep downstream pressure constant despite fluctuating inlet conditions, making PRVs reliable choices for industrial and utility networks.

Benefits of Pressure Reducing Valves

- Maintains constant downstream pressure under varying inlet loads

- Minimises energy losses caused by excessive throttling

- Protects pumps, exchangers, seals, and instruments from overpressure

- Reduces surge effects and water hammer in pipelines

- Reliable for continuous duty in industrial and utility networks

Types of Pressure Reducing Valves

- Direct Acting PRV – compact and quick-acting at points of use

- Steam Pressure Reducing Valve – stabilises steam delivery for boilers and process heating

- Water Pressure Reducing Valve – dependable control in potable and industrial water systems

- Pilot Operated PRV – high accuracy and capacity for large pipelines and varying demand

- Pressure Relief & Sustaining Valve – prevents overpressure while maintaining upstream levels

- Float Control Valve – regulates storage tank levels and inlet flows

Design Standards

- BS EN 1567 – Water PRVs

- ISO 23555 series – Gas pressure regulators and safety devices

- ASME B16.34 – Valve design and pressure-temperature ratings

- EN 334 – Gas regulator standards

- Compatible with ASME B31.1 and B31.3 piping codes

Inspection and Testing Standards

- API 598 – Shell and seat pressure testing

- ISO 5208 – Metallic valve pressure testing

- MSS SP 61 – Hydrostatic and pneumatic tests

- In-house functional and set-point verification

- Certified for leakage and accuracy compliance

Technical Specifications

- Size Range: DN 15 to DN 600

- Pressure Ratings: PN 10 to PN 250; ASME Class 150 to 600

- Set Pressure Range: 0.2 bar to 25 bar (direct acting); wider with pilot-operated designs

- Temperature Range: −20 °C to 220 °C (depending on material and media)

- End Connections: flanged RF/RTJ, butt weld, socket weld, threaded (smaller sizes)

- Control Accuracy: ±10% of set point (direct acting); ±1–2% (pilot operated)

- Body Patterns: globe or angle body, with soft or metal seat options

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Stainless Steel | F304, F316, F321, F347 | ASTM A351 (cast) / A182 (forged) | Steam lines, chemical utilities, corrosive water |

| Carbon & LTCS | WCB, WCC, LCB, LCC | ASTM A216 (WCB/WCC) / A352 (LCB/LCC) | Hydrocarbons, chilled water, general service |

| Duplex & Super Duplex | F51, F53, F55, 2507 | ASTM A890 (cast) / A182 (forged) | Seawater duty, RO plants, offshore platforms |

| Bronze & Aluminium Bronze | C83600, LG2, C95400, C95800 | ASTM B62 (bronze) / B148 (Al-Bronze) | Marine, brackish water, fire water lines |

| Alloy 20 | CN7M | ASTM A351 / A182 | Acidic media, pickling lines |

| Hastelloy | C276, B3 | ASTM B574 / B622 / B626 | Aggressive and oxidizing chemical service |

| Inconel | 600, 625, 718 | ASTM B166 / B564 | High temperature and pressure duties |

| Titanium | Grade 2, Grade 5 | ASTM B348 / B381 | Chloride-rich water, specialty chemical services |

Industries Served

- Oil & Gas – utilities, refineries, distribution networks

- Power Generation – boiler auxiliaries, steam conditioning, condensate lines

- Water & Desalination – treatment plants, distribution systems, storage tanks

- Petrochemical – utilities and process units

- Marine & Offshore – ballast, fire water, and cooling water lines

- Mining & Metals – reagent dosing, plant utilities

- Industrial Utilities – nitrogen, compressed air, plant water

Special Features

- Modular pilot cartridge for easy maintenance

- Downstream sensing port with gauge tap and block bleed

- Interchangeable soft or metal seat configurations

- Surge-damping needle for stable control under fluctuating loads

- Coating and elastomer options for potable water and seawater service

- Customisation to suit flow rate, service conditions, and material preferences

Mid-body note: we are a valve manufacturer with in-house testing capability, offering documentation aligned to international standards for regulated projects.

As a trusted Pressure Reducing Valve Supplier in Dubai, we support local industry needs with compliant PRV assemblies built for accuracy, reliability, and maintainability.

Showing all 6 results