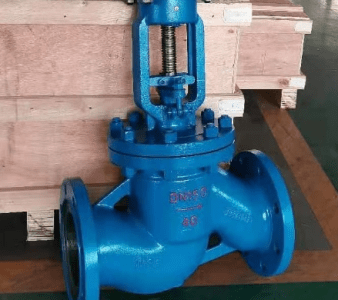

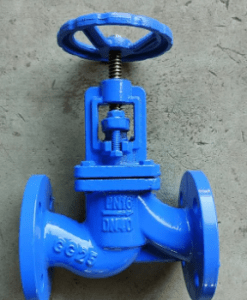

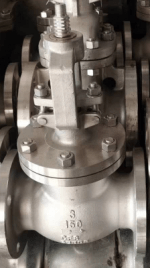

Globe Valve

Globe Valve Supplier in Dubai UAE Valves supplies rising stem globe valves for accurate throttling and secure shutoff in process, power, and water service. The plug moves toward or away from the seat to trim flow, and the body flow path gives predictable control that helps steady conditions on both sides of the valve. With guided trims, erosion resistant seating, and accessible bonnets, operators get stable set points and straightforward maintenance over the life of the valve.

How Globe Valves Work

Inside the body, flow changes direction across the seat. The stem raises a plug to increase flow or lowers it to reduce or stop it. Because the seat and plug meet in a controlled way, the valve can hold a set opening for regulation or close tightly for isolation. Trim shapes such as tapered or parabolic help match the valve to the control task, while hardfacing protects sealing surfaces when differential pressure is high.

Globe Valve Benefits

- Steady, repeatable control that helps loops stay on target

- Tight isolation from robust plug and seat contact

- Clear position indication from the rising stem for safe operation

- Trim choices that manage noise, cavitation, and flashing where needed

- Easy service thanks to top entry bonnet and accessible packing set

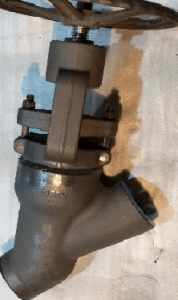

Types of Globe Valves

- Iron Globe Valve: cost effective option for water and utility service

- Steel Globe Valve: built for higher pressures and temperatures in process duty

- Bellow Seal Globe Valve: zero stem leakage for toxic, volatile, or hot media

- Angle Globe Valve: body turns the line by ninety degrees for drains or erosive duties

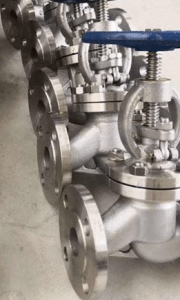

- Forged Steel Globe Valve: compact small bore isolation and control with threaded or socket weld ends

- Y Type Globe Valve: low pressure loss path for steam and high differential control

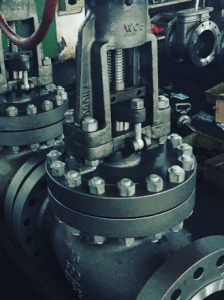

- Pressure Seal Globe Valve: pressure energized bonnet seal for high pressure power service

Technical Specifications

- Size range: DN 15 to DN 600 (½ in to 24 in)

- Pressure ratings: PN 10 to PN 250; ASME Class 150 to 2500

- Temperature range: −196 °C to +600 °C depending on materials

- End connections: flanged RF or RTJ, butt weld, socket weld, threaded for small sizes

- Face to face: ASME B16.10 and EN 558 series

- Flow characteristics: linear or equal percentage trims for regulation

Design Standards

- API 623 and BS 1873 for globe valve design

- ASME B16.34 for design and pressure temperature ratings

- ASME B16.5 and B16.47 for flanges; ASME B16.10 for face to face dimensions

- ISO 5208 and EN 12266 for pressure testing where specified

Inspection and Testing

- API 598 hydrostatic shell and seat tests, with ISO 5208 leak rates on request

- Fire testing to API 6FA when a fire tested assembly is required

- Fugitive emission testing to ISO 15848 for low emission packing options

As a manufacturer, we log test results and issue traceable EN 10204 3.1 or 3.2 certification packs with serial level data.

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC, LCB, LCC | ASTM A216 / ASTM A352 | Steam, hydrocarbons, utilities |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, brackish water |

| Forged Stainless | F304, F304L, F316, F316L | ASTM A182 | High pressure throttling trims |

| Alloy Steels | WC6, WC9 | ASTM A217 | High temperature steam service |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / ASTM A890 | Seawater, chloride rich duties |

| Super Austenitic Stainless | F44 (254SMO) | ASTM A182 / ASTM A351 | Desalination, high chloride service |

| Nickel Alloys | Monel 400, Inconel 625, Inconel 718 | ASTM B564 | Sour gas, aggressive media |

| Hastelloy | C276, B3 | ASTM B574 / ASTM B564 | Oxidizing or halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid service |

| Bronze / Aluminium Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and seawater systems |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702, R60705 | ASTM B348 / ASTM B493 | Chlorides, seawater, specialty acids |

Industries Served

- Oil and gas: unit isolation, control stations, pump recirculation

- Power generation: steam conditioning, attemperation lines, drains

- Water and desalination: plant headers, dosing lines, high pressure circuits

- Petrochemical: reactors, columns, heat exchanger bypasses

- Marine and offshore: utility lines and seawater service with duplex materials

- Mining and metals: slurry side streams using Y type or angle patterns

As a Globe Valve Supplier in Dubai, we support existing plants and new builds with sizing, materials, and documentation aligned to project requirements.

Special Features

- Quick change trim cartridges and removable seat rings to shorten maintenance windows

- Multi stage low noise and anti cavitation cages for severe differentials

- Travel stops and stroke limiters to set safe control ranges

- Lantern ring and leak detection ports for monitoring packing condition

- Equalizing bypass kits to lower opening torque on high differential starts

- Top works with position switches or transmitters for remote status

Customization available for trim style and characteristic (parabolic, V port, multi stage), seat leakage class to ANSI/FCI 70-2, actuator type and signal, end connections, coatings, and materials to match your service and documentation needs.

Showing all 14 results