Gate Valve

Across Dubai’s oil, gas, power, and water networks, UAE Valves is a Gate Valve Supplier in Dubai delivering positive isolation with low pressure drop for safe maintenance and steady operations. We support EPCs and plant teams with application sizing, documentation packs, and materials that match local seawater and process conditions.

How Gate Valves Work

A gate valve uses linear motion to move a wedge or slab across the flow path. When the gate lifts fully, the bore is open and pressure loss is minimal; when it lowers, the seating surfaces compress to isolate the line. Wedge designs suit general service, while parallel slide and through conduit designs provide tight isolation on steam and pipeline duty. Rising stem OS and Y gives clear position indication; non rising stem saves space in pits and underground boxes.

Gate Valve Benefits

- Full or near full bore design for very low pressure drop

- Bidirectional isolation that improves maintenance safety and leakage control

- Hardfaced seats and guides for long service life in erosive duty

- Wide choice of manual and automated operators

- Proven performance in onshore, offshore, and desalination environments

Types of Gate Valves

- Rising Stem Gate Valve (OS and Y): clear position indication and easy packing access for above ground installations

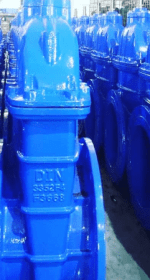

- Non Rising Stem Gate Valve: compact, protected stem for buried service and tight spaces

- Bellow Seal Gate Valve: zero stem leakage design for toxic or high temperature media

- Double Disc Gate Valve: parallel double disc for tight sealing with low operating torque

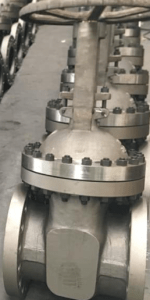

- Forged Steel Gate Valve: API 602 small bore utility and high pressure block points

- Pressure Seal Gate Valve: pressure energized bonnet seal for high temperature and high pressure power service

Technical Specifications

- Size range: DN 15 to DN 1200

- Pressure ratings: PN 10 to PN 250; ASME Class 150 to 2500

- Temperature range: −196 °C to +600 °C depending on materials

- End connections: flanged RF or RTJ, butt weld, socket weld, threaded for small sizes

- Face to face: ASME B16.10

- Bore options: full bore for API 6D pipeline valves; reduced bore on selected plant valves

- Operators: handwheel, bevel gear, electric, pneumatic, or hydraulic actuators

Design Standards

- API 600 (steel gate), API 602 (forged), API 603 (stainless), API 6D (pipeline)

- ASME B16.34 for design and pressure temperature ratings

- ASME B16.5 / B16.47 for flanges; ASME B16.10 for face to face

- ISO 5208 / EN 12266 pressure testing where specified

Inspection and Testing

- API 598 hydrostatic shell and seat tests; ISO 5208 leak rates on request

- API 6D testing for pipeline valves including double block and bleed verification where applicable

- Fire safe qualification to API 607 or API 6FA when specified

- Low emission packing options with ISO 15848 or API 641 performance

As a manufacturer, we record test data and provide traceable material and certification packs to EN 10204 3.1 or 3.2.

Body and Trim Material Compatibility

| Category | Material / Grade | Standards / Grades | Typical Applications |

|---|---|---|---|

| Carbon Steel | WCB, WCC, LCB, LCC | ASTM A216 / ASTM A352 | Hydrocarbons, steam, general service |

| Cast Stainless Steel | CF8 (304), CF8M (316), CF3M | ASTM A351 | Corrosive media, oxygen clean services |

| Forged Stainless | F304, F304L, F316, F316L | ASTM A182 | High pressure utility and process lines |

| Alloy Steels | WC6, WC9 | ASTM A217 | High temperature steam service |

| Duplex / Super Duplex | F51 (2205), F53, F55 (2507) | ASTM A182 / ASTM A890 | Seawater, RO, offshore environments |

| Super Austenitic Stainless | F44 (254SMO) | ASTM A182 / ASTM A351 | Desalination and chloride rich seawater service |

| Nickel Alloys | Monel 400, Inconel 625, Inconel 718 | ASTM B564 | Sour gas, high temperature, aggressive media |

| Hastelloy | C276, B3 | ASTM B574 / ASTM B564 | Oxidizing or halogenated media |

| Alloy 20 | CN7M | ASTM A351 | Sulfuric acid and chemical duty |

| Bronze / Aluminium Bronze | C83600, C95400, C95800 | ASTM B148 | Marine and brackish water systems |

| Titanium / Zirconium | Ti Gr.2, Gr.5; Zr R60702, R60705 | ASTM B348 / ASTM B493 | Chlorides, seawater, specialty acids |

Industries Served

- Oil and Gas: trunk lines, manifolds, unit block valves

- Power Generation: main steam isolation, boiler lines, condensate headers

- Water and Desalination: transmission mains, plant headers, intake and outfall lines

- Petrochemical: process units, utility manifolds, tank farm isolation

- Marine and Offshore: topside utilities, fire water, seawater cooling

- Mining and Metals: slurry transfer, plant water

As a Gate Valve Supplier in Dubai, we support existing facilities and new builds across the Middle East. Available as industrial gate valves for Dubai projects and specified for regional export.

Special Features

- Backseat arrangement for stem seal maintenance under no pressure

- Bypass valves for pressure equalization across the gate before opening

- Stem extensions and gear operators for buried or elevated installations

- Position switches and limit feedback for remote monitoring

- Grease injection fittings and drain taps where maintenance strategy requires

Customization available for bore, end connections, operator package, coatings, and materials to match project specifications.

Showing all 13 results