About

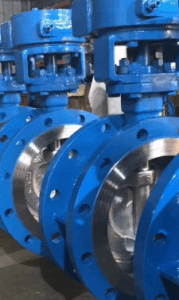

Double flanged butterfly valve are a particular variety of butterfly valve that has flanged ends on reciprocals of the valve body. They are often employed in large diameter piping systems where a safe a leak tight attachment is necessary.

Function

● To control the flow of fluids.

● To control throttle and regulate the flow of fluid.

● Can perform well in high temperatures.

Advantages

● Design provides double sealing minimizing fluid leaks and making them best possible for an intense environment.

● Their lightweight and compressed structure permits for easy installation and minimizes the system’s overall weight, making them favored in applications where space is limited.

● They are respectively reasonably priced and require less maintenance than other valve types.

● It has low maintenance cost.

Industries Using

● Oil and gas

● Chemical

● Power generation

Components

● Body: The body is the external part of a double flanged butterfly valve that holds the internal part of the valve.

● Handwheel: The handwheel imparts the force needed to rotate the disc to open and shut the valve.

● Stem: It is used to connect the handwheel and the valve disc.

● Gear box: It transmit rotation from handwheel to the valve stem

● Disc: It is assigned to open and close the valve.

● Seat: This is a component that forms a facet for the disc to let up when the valve is closed.

● Gasket: Prevent the fluid drip between the valve and pipe mating surface.

Description:-

1. Available materials: Cast iron, Ductile iron, SS304, SS316,

WCB,WCC,WC6, LCB, LCC, SS316L, F55, F53, F51

2. Size: 2” to 72”

3. Class: 150 to 300

4. Nominal Pressure: PN6 to PN25

5. Ends: Flanged

6. Operations: Gear Operated, Electric and Pneumatic Actuated, Lever

Operated

7. Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA

Showing the single result