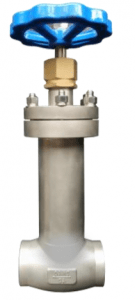

Cryogenic Valve

As a leading Cryogenic Valve Supplier in Dubai, UAE Valves provides engineered solutions that withstand temperatures down to –196°C for LNG, petrochemical, and industrial gas applications. Built to international standards, our cryogenic valves deliver safe, leak-tight, and reliable performance in processes where precision and safety are non-negotiable.

How Cryogenic Valves Work

Cryogenic valves are specifically designed to handle fluids at extremely low temperatures. They feature extended bonnets that keep stem packing insulated from cryogenic liquids, preventing frost damage and ensuring smooth operation. Carefully selected trims, seals, and body materials minimize contraction stress and guarantee tight shutoff even under demanding conditions.

Cryogenic Valve Benefits

- Ensures safe, leak-tight service at cryogenic temperatures.

- Extended bonnet design prevents stem freezing.

- Maintains reliable sealing under thermal contraction.

- Smooth actuation with low torque requirement.

- Qualified and tested to international cryogenic standards.

Types of Cryogenic Valves

- Cryogenic Emergency Cut Off Valve – fast shutoff in critical emergency conditions.

- Cryogenic Short Stem Globe Valve – compact design for space-limited installations.

- Cryogenic Long Stem Globe Valve – extended stem for operator safety and accessibility.

- Cryogenic Steam Jacket Globe Valve – prevents medium solidification inside pipelines.

- Forged Cryogenic Trunnion Ball Valve – suited for LNG and liquid gas transfer.

- Cryogenic Ball Valve – quarter-turn on/off control for cryogenic service.

- Cryogenic Gate Valve – ensures reliable isolation in cryogenic pipelines.

- Cryogenic Check Valve – stops reverse flow in cryogenic systems.

- Cryogenic Pneumatic Actuated Globe Valve – provides automated throttling for cryogenic operations.

Design Standards

- Globe Valves: BS 6364, ASME B16.34, API 623, ISO 28921-1

- Ball Valves: BS 6364, API 6D, ISO 17292

- Gate Valves: API 600, BS 6364, ASME B16.34

- Check Valves: API 594, BS 6364, ISO 28921-1

Inspection and Testing Standards

- BS 6364 – Cryogenic Valve Testing

- API 598 – Valve Inspection and Pressure Testing

- ISO 28921-2 – Cryogenic Qualification Testing

- MSS SP-134 – Design & Testing for Cryogenic Valves

Body and Trim Material Compatibility

| Material | Grade | Applications |

|---|---|---|

| Stainless Steel | F304, F316, F317L, F321, F347 | LNG plants, cryogenic pipelines, air separation units |

| Duplex / Super Duplex | F51 / 2205, F53, F55, 2507 | Offshore LNG terminals, high-strength cryogenic systems |

| Alloy 20 | CN7M | Corrosive cryogenic chemical service |

| Hastelloy | C276, B3 | Aggressive chemical and oxidizing cryogenic media |

| Inconel | 600, 625, 718 | High-pressure cryogenic and low-temperature gas service |

| Titanium | Grade 2, Grade 5 | Aerospace and chlorine-rich cryogenic services |

| Bronze / Aluminium Bronze | C83600, LG2 / C95400, C95800 | Marine cryogenic lines, offshore service |

| Zirconium | R60702, R60705 | Highly corrosive cryogenic plants |

Each valve is tested and certified in-house by our experienced engineers, reinforcing our role as a trusted manufacturer for critical cryogenic service.

Industries Served

- Oil & Gas – LNG production and regasification

- Petrochemical – cryogenic storage and pipelines

- Power Generation – gas liquefaction and cooling units

- Marine & Offshore – LNG carriers and terminals

- Industrial Gases – oxygen, nitrogen, hydrogen plants

- Water Desalination – low-temperature brine service

- Mining & Metals – cryogenic cooling and refining

Special Features

- Extended bonnet options for safe operation at –196°C.

- Fire-safe and anti-blowout stem construction.

- Flexible actuation choices: manual, pneumatic, or electric.

- Available in DN 15–1200 and pressure ratings up to Class 1500.

- Customization available — bonnet length, trim design, and actuation can be tailored for plant-specific needs.

Showing all 9 results