Its design features a full sealing system enabled by multiple walled bellows, a sealed two-part rising stem, and a stellite-coated, conically shaped piston and seat. It is a great choice whenever leakage to the atmosphere is intolerable due to toxicity, chemical corrosion, radioactivity, etc. It contains a rising stem, non rising handwheel, yoke and yoke cap, one piece bonnet forging, flanged or forged ends, grease nipple with lubricant baking, packing gland, long bellows, bonnet and the seats.

The valve is similarly a gate valve which is supported but the bellows. The long rising stem goes all the way from inside the valve body to the hand wheel. The Bellow Seal Gate Valves are used in high pressure systems and are connected to the pipes with flanged connections. The connection can also be by means of socket, welded or NPT threaded ends of the pipes.

Design & function

Design

- The structure is simple and standard that has a rotation-less stem and handles to avoid bellows twisting.

- The structure further has gland packing that helps prevent external leakage. Its structural design for the bolt is convenient to maintain and manage with the bolt being tightened and that ensures quick and safe fastening.

- The hydraulic multi-layer bellows are used that feature excellent features and corrosion resistance.

- For the upper gasket, the expanded graphite seat is used to restrict the external leakage in the event of bellows breakage.

Function

The primary purpose of bellows in valves is to provide a flexible, leak-proof seal that protects the stem from corrosion and prevents fluid from eroding the stem. Bellows are also used to compensate for changes in temperature and pressure in the system, which allows the valve to operate smoothly and efficiently

Advantages of Bellows Seal Globe Valve

1. The most well known advantage of any bellows valve is the Double seal design So, even if the bellows go wrong, the stem packing will prevent any kind of leakage to meet the international sealing .

2. lower any loss of the medium fluid and secure the safety and environmental protection. This will improve the safety of the plant where the bellows valve has been placed.

3. It can act as an energy saver as it contributes to lowering energy losses due to leakage.

4. because the leakage is minimized, it prevents continuing maintenance of the valve. So, it helps to extend valve life.

5. Owing to longer service life, operating and maintenance cost is considerably reduced.

6. The rugged bellows seal design secures zero leakage from the valve stem, thereby providing the maintenance-free conditions.

7. The safety of working personnel is improved with the installation of a bellows valve as release of inflammable, toxic, and hazardous chemicals can be minimized.

Description

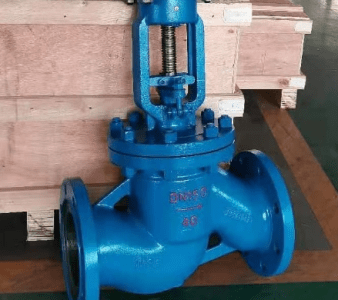

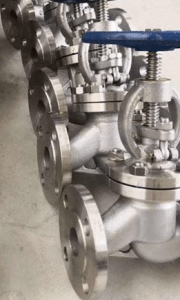

1. Material: Cast Iron, Cast steel [LCB, LCC, WCB, WCC, WC6, WC9], Ductile Iron, Stainless Steel [CF8, CF8M, F3, F304, F316, F31L, F51, F55, F91, SS304, SS316, SS316L, SS904L]

2. Class: 150- 2500; PN25- PN450

3. Size: ½” to 24”

4. Ends: Flanged, Buttweld, Socket weld, Threaded

Showing all 4 results