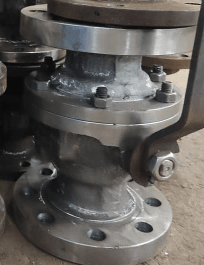

UAE Valves is a leading Alloy 20 Floating Ball valve supplier in Abu Dhabi. Floating ball valve made of Alloy 20 is a valve type designed to be used in aggressive chemical environments. The valve is made of Alloy 20, a type of corrosion-resistant alloy that mostly contains nickel, iron, and chromium. The ball of this valve is not fixed but floats between two valve seats. Under pressure, the ball floats and is pushed against the down-stream seat, preventing it from leaking. This one is useful for highly corrosive acids and other fluids; therefore, it is used in the chemical processing, chemical, and petrochemicals.

An Alloy 20 floating ball valve works by turning a spherical ball that has a central bore rotating inside the valve body. A ball pivots in response to the valve handle or an actuator, forcing the bore through the upstream and downstream. If the bore aligns perfectly with the flow path, the valve is in the open position. If, however, the bore is perpendicular to the flow path, the valve is closed. A ball floats between two seats in a floating ball design. As pressure from the fluid increases, the ball slides toward the downstream seat. This action presses against the seat forcing it into the seal, preventing leakage. Fluid flows quickly through the float ball valve, making it less prone to fluid erosion. Therefore, the valve can maintain control of fluid and sealing in a corrosive environment for quite a duration.

UAE Valves is a topmost Alloy 20 Floating Ball valve supplier in Abu Dhabi, they have valves with various advantages:

•Corrosion resistance is improved. Suitable for aggressive chemicals and severe environmental conditions.

•Sealing is dependable. The floating ball design compresses the ball against the downstream seat for a tight seal.

•Durable in performance. The gadget will serve you for a long time, even in severe operating conditions.

•Smooth operation. It is easy to control the valve and precisely manage the fluid flow.

•Low maintenance. The valve does not require regular maintenance, reducing operation costs.

Industries:

•Chemical Processing

•Petrochemicals

•Pulp and Paper

•Water Treatment

•Mining and Mineral Processing

•Oil and Gas

•Power Generation

•Marine

•Textile Industry

Showing the single result